Nylon 66 Uses

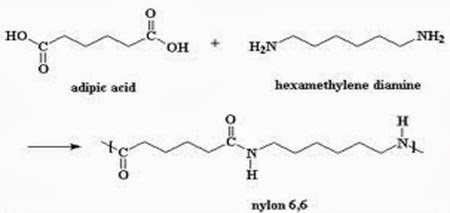

Nylon 66 is a type of polyamide or nylon. Nylons come in many types, and the two most common for textile and plastics industries are nylon 6 and nylon 6 6. Nylon 66 is made of two monomers each containing 6 carbon atoms, hexamethylenediamine, and adipic acid, which give nylon 6 6 its name.

Nylon 66 Uses:

Nylon 66 is frequently used when high mechanical strength, rigidity, good stability under heat and/or chemical resistance are required It is used in fibers for textiles and carpets and molded parts. For textiles, fibers are sold under the Cordura brand for luggage, but it is also used in airbags, apparel for carpet fibers under the Ultron brand. Nylon 66 lends itself well to make 3D structural objects, mostly by injection molding finding broad use in auto application under the hood such as radiator end tanks, rocker covers, air intake manifolds, oil pans and numerous other structural parts such as ball bearing cages, electro-insulating elements, pipes, profiles and various machine parts.zip ties, conveyor belts, hoses, polymer framed weapons, and the outer layer of turnout blankets. Nylon 6 6 is also a popular guitar nut material.

Use of Nylon 66 in Fiber Manufacturing:

The processing of nylon usually begins by conditioning the received chip, with or without an increase in the received molecular weight. The chip is then melted, usually in a screw-type extruder, and spun into filament form. The filaments are then packaged in a process that may include drawing, bulking, or cutting into lengths of the staple.

Additional Information on Nylon 66:

- Chemical formula: (C12H22N2O2)n

- Density: 1.314 g/mL (Zytel)

- Melting point: 507 °F (264 °C)

Uses of Nylon 66:

Related Links – Properties of Nylon 66 and Preparations of Nylon 66